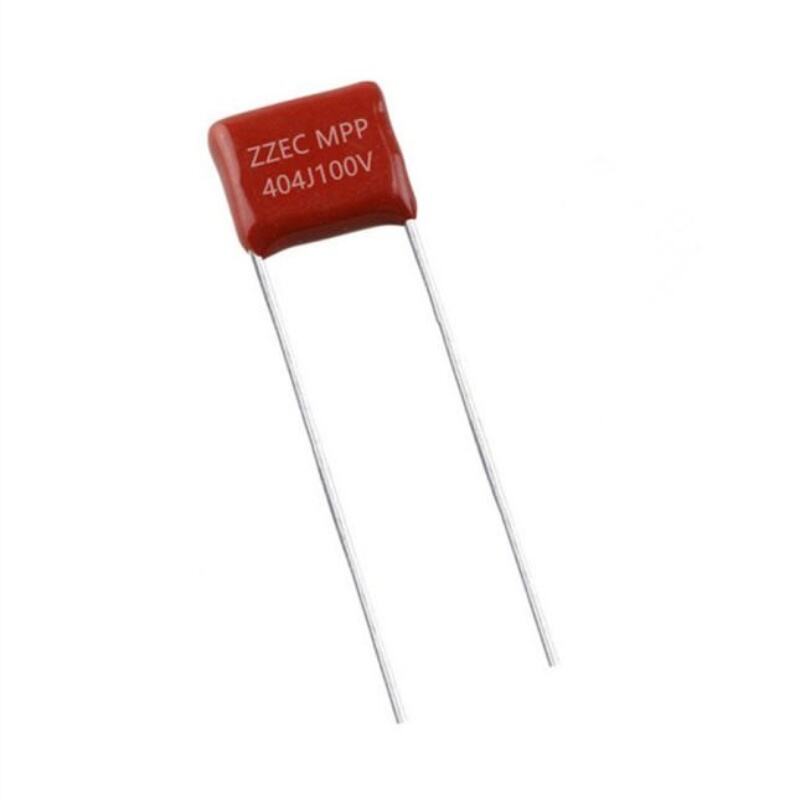

What is a Met Film Capacitor? It consists of two metal plates separated by a thin layer of dielectric material (polystyrene, polypropylene or polyester). Met Film capacitors are known for their reliable performance in electronic application with significantly lower lost energy and higher-time stability.

Capacitors provide the electrical power storage as batteries do for electronic devices. Using a film, which in Michigan-based Plastic Capacitors case is typically made of polyester-type material such as polypropylene or polycarbonate and placed between two metal layers. One of the prestigious features found in met film capacitors is that it can able to handle even 1000 volts where these specifications make them get a long life as well enhance its performance level. These capacitors are in addition also having low dissipation factor and thereby use energy more efficiently than other style of amplifiers to produce less heat.

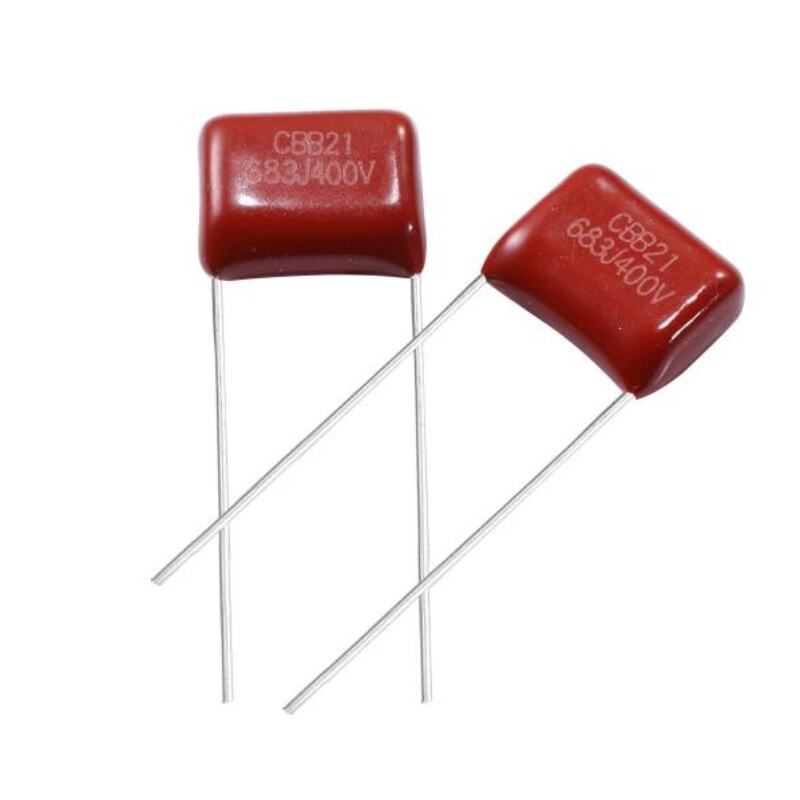

Amongst other varieties of capacitors, the met film capacitor has a number features and benefits that make it distinct. They are ideally suitable for high electrical energy consumption applications, as they can also bear voltages up to 1000 volts. In addition, high insulation resistance decreases the chance of short circuits. Additionally, they have a very low dissipation factor that enables them to run with minimal heat generation.

With its safety conception the metallized film capacitor is an environmentally friendly and non-toxic designed product. They have waterproof and degrading resistant built so that they can be durable for longer periods, providing continuous accuracy. Furthermore, the capacitors are designed to work at such high temperatures which should help reduce thermal runaway risks that often occur with other types of capacitor.

Using a MET film capacitor is as easy. It just need to feel in between the power source and device alike connecting a battery. Aligning the positive and negative terminals is necessary to avoid possible destruction of the capacitor itself or by using this terminal damage do your dispositive.

Met film capacitors are used in power supplies, lighting, motor control and audio equipment. Therefore, their reliability and stability are critically important - particularly for automotive and aerospace where rock steady performance gives the edge. The manufacturers that use these met film capacitors can build safe, reliable and long-lasting products. Stringent testing processes lead to exceptional quality and reliability, which are crucial factors in mission-critical applications as those used in space technology.

ZZEC was established in 2007. is a mix of R D and production, marketing, one enterprise. ZZEC has a dust-free standard workshop, advanced labs, production equipment. Our high-quality production process and equipment are able provide real-time temperature information met film capacitorproduction phase.

ZZEC has achieved IOS900, RoHS, REACH other reputable certifications. pay a lot attention to the quality of products. We has strict quality control procedures testing procedures. In addition ZZEC is planning to launch in 2022 most advanced German Leybold coating met film capacitor, and also the establishment an expert Japanese team.

ZZEC is enterprise that focuses on R D, manufacturing and sales premium, ultra-small film met film capacitor. currently has an annual output about 3 billion capacitors. These capacitors used in many applications, including audio, industrial control well as wireless charging.

provide customized services, flexible adjustments according the requirements of our met film capacitor, provide pre-sales technical solutions and direct docking with engineers working development whether it's specifications, performance, printing, etc. We are able to meet the needs each customer and export to a variety countries

Baixiang Industrial Zone, Yueyang County, Hunan Province

+86 13632246380

+86 13902496593

+86 13902496752